|

|

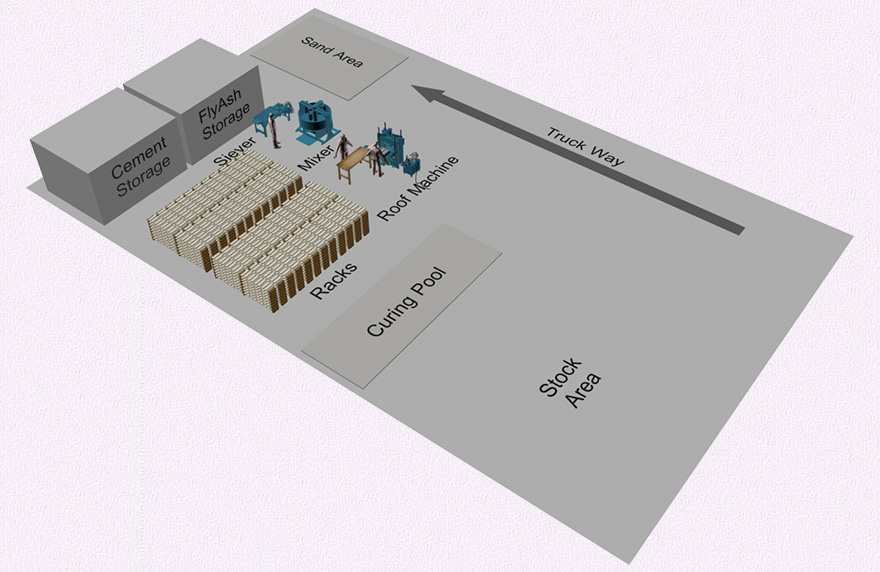

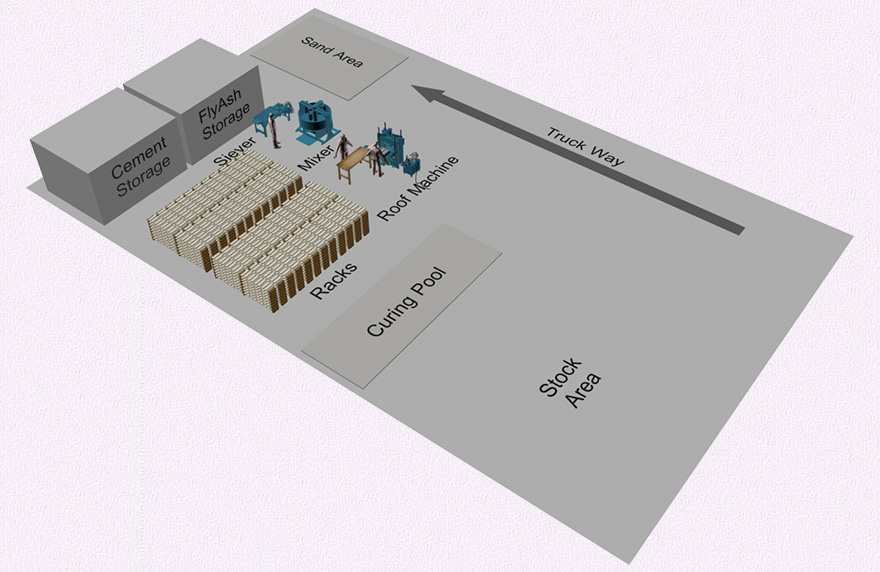

CONCRETE ROOF TILES PRODUCTION LAYOUT

|

|

Planning the LayOut of your

concrete roof factory is very

important . The materials , the

machines , the racks , the

watering container , and etc ,

should be placed in good

position so the works flow can

be good and fine .

The

raw material ( Cement , Sand ,

Calsium Powder ) should be near

by the Mixer . And the sand

should be near by the Siever .

And after the sand has been

seived , all the material will

be put into the Mixer . Then

after the material mixed , the

mortar will delivered to the

Roof Machine . Then the printed

roofs will be put on the racks.

And

at the second day , the printed

roof will be put into water for

1 day . The third day , the roof

can be placed in the stock

places , and after 2 week the

roof will ready to be paint or

deliver to your customers .

Notes :

|

1. |

Trucks have to be easily

reach the material area

and the stock area . |

2.

|

Usually Stock Area is

placed in the front of

the factory area , and

the material in the back

, and the production

area in the middle .

Because some of factory

owner not willing to

show the production area

and the material area to

customers or factory

visitors . |

|

3. |

By understanding the

flow chart , you will

understand the layout

and the flow of the

production system . |

|

4. |

The size of the land is

depend on how many

machines that you want

to install on it . For

only 1 production line ,

we recommend at least

you have 500 m2 of land

. |

|

|

|

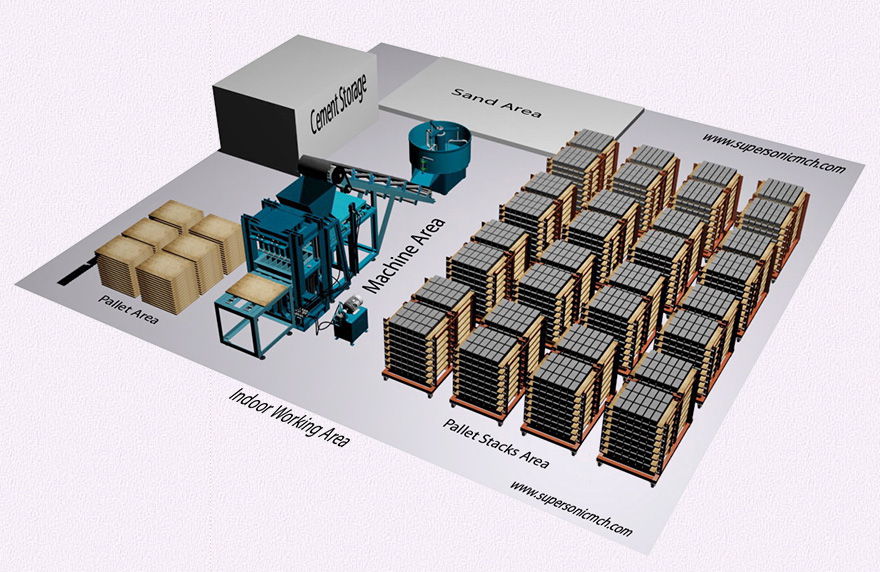

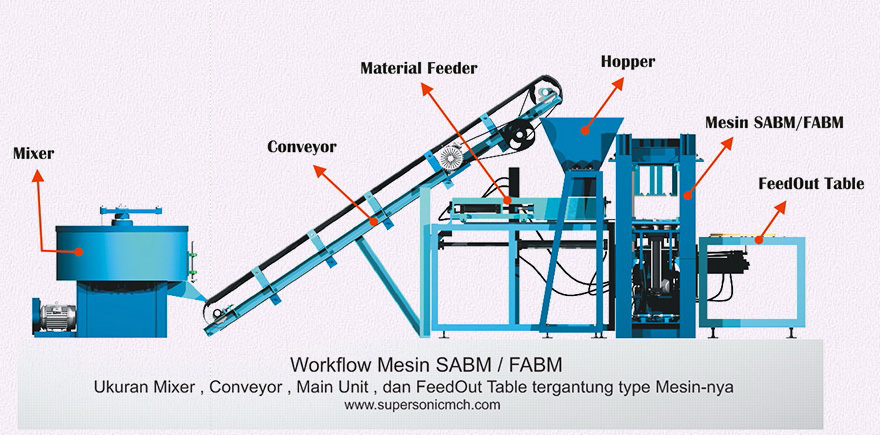

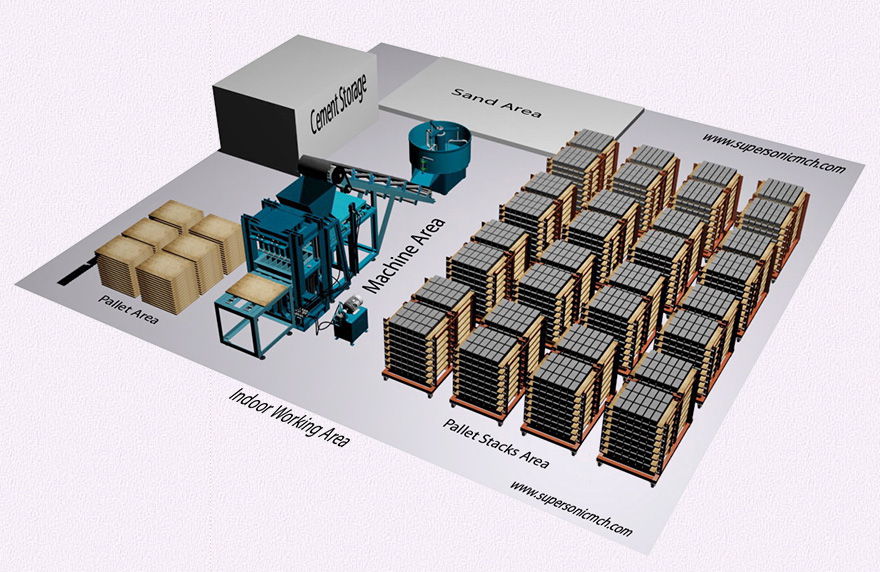

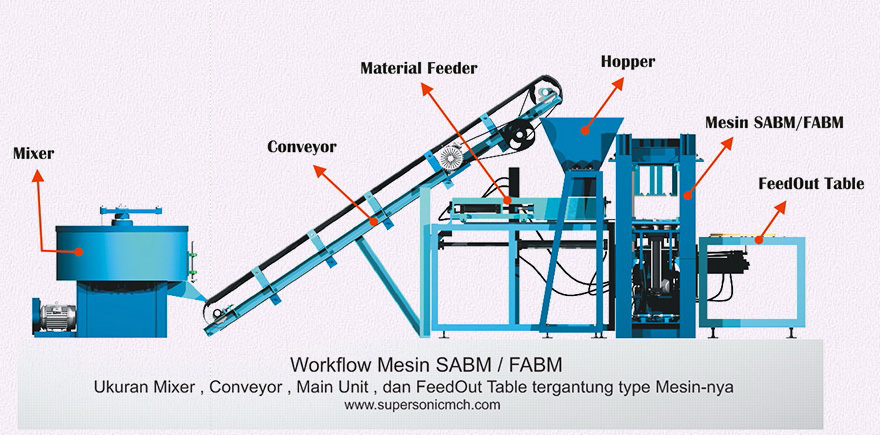

PAVER / BLOCK PRODUCTION LAYOUT

| |

The

raw material ( Cement , Sand ,

Calsium Powder ) should be near

by the Mixer . Then all the

material will be put into

the Mixer . Then after the

material mixed , the mortar

will delivered to the

Pressing Machine by the

conveyor . Then the printed

pavers will be put on the racks.

And

at the second day , the

printed pavers will be put into water for

1 day ( or sprayed with water )

. The third day , the pavers

can be placed in the stock

places , and after 2 week

the pavers will ready to deliver to your customers .

Notes :

|

1. |

Trucks have to be easily

reach the material area

and the stock area . |

2.

|

Usually Stock Area is

placed in the front of

the factory area , and

the material in the back

, and the production

area in the middle .

Because some of factory

owner not willing to

show the production area

and the material area to

custumers or factory

visitors . |

|

3. |

By understanding the

flow chart , you should

understand the layout

and the flow of the

production system . |

|

4. |

The size of the land is

depend on how many

machines that you want

to install on it . For

only 1 production line ,

we

recommend at least

you have 500 m2 of land

. |

|

|

|

|

|

|