|

|

CONCRETE ROOF MACHINE OPERATION MANUAL

| |

|

1. ELECTRIC PREPARATION

: |

The electric needed to

supply the machines and

accessories is depend on

the numbers of the

machines .

For the basic plan ( 2

Pressing Machines , 1

Mixer , and 1 Sand

Siever ) , you will have

to prepare 15 Kva of

electric plan .

There are 2 choices of

preparing the electric

plan :

A. Using the Electricity

, you need to have at

least 12 Kva from the

Electricity Company .

B. Using an Electric

Generator . In this case

you have to prepare a 15

Kva of Electric

Generator . There are

many kinds and brand of

electric generator , and

we also provide electric

generator , please click

here to see our offer

for electric generator .

It is also recommended

to have both electric

plan ( the electricity

and the generator ) , so

you always has back up

power when the

electricity down .

|

|

|

| |

|

2. SETTING UP THE

MACHINE : |

The pressing machine's

oil tank need to be

filled by hydraulic oil

as the tank isn't

supplied with the oil .

There are many kinds of

hydraulic oil in the oil

shop at the market , you

can use the hydraulic

oil with measurement of

SAE 10 or SAE 20 . SAE

is a measurement number

of oil thickness . Or

you can just use the car

or motorcycle engine oil

, with measurement of

SAE 20 .

|

2.0 Setting Up

The Electric

Power to the

Machine |

Photo 1 |

Photo 2 |

|

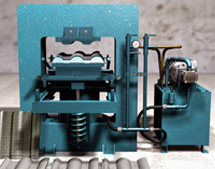

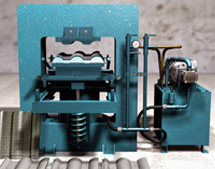

2.1

For safety

reason during

shipment , we

always separate

the pressing

machine and the

power pack , and

put some

important

spareparts into

the oil tank .

So please open

the oil tank and

take out all the

spareparts . Set

the machine with

the power pack

like in the

pictures .

( The black hose

is set for

hydraulic

pressure and the

white hoses for

circulation

system ) .

|

|

|

|

2.2

First after you

put the machines

and the

accessories to

right place ,

you need to set

the electric

wire to each

machine . Each

machine have one

electric motor ,

and the electric

motor type is

3-phase electric

consumption . So

you need to set

4 wire from the

factory electric

outlet ( 3

positive and 1

negative pole )

. Open the

electric motor

pole cover and

see the

instruction on

the back of the

pole cover .

|

|

|

|

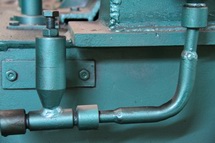

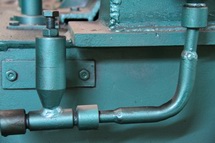

2.3

After you put

the electric in

, before you

turn the

electric on ,

please check the

Machine Valve ,

and make sure

the both valves

are in open

state ( anti

clockwise ) .

Because if the

valves are

closed when you

turn the

electric power

on , then the

hydraulic press

will operated

and pressing an

empty mold which

may cause damage

on the mold .

But if the

valves in open

condition then

the hydraulic

press will

remain inactive

.

|

|

|

|

2.4

Now you can turn

the electric on

and check the

moving direction

of the electric

motor by

checking at the

arrow direction

printed on the

hydraulic pump .

It should be

anti clockwise ,

if not then you

should reverse

two of the three

electric pole

you put into the

electric motor .

Then the

direction will

spin to the

correct

direction .

|

|

|

|

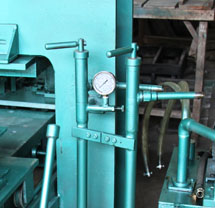

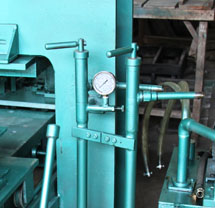

2.5

You may also

adjust the

pressure by

adjusting the

relief valve .

Check the

pressure shown

on the pressure

gauge . The

normal pressure

for casting roof

is 100 to 200

bar , for barge

or verge is 100

bar , and for

casting pave is

also 100 bar .

|

|

|

|

2.6

You should also

prepare a table

beside the

Machine too , to

make the work

easier .

|

|

|

|

|

|

And because the process will have wasted

water , you also need to prepare a

gutter around the machine for wasted

water going out of working area .

|

|

|

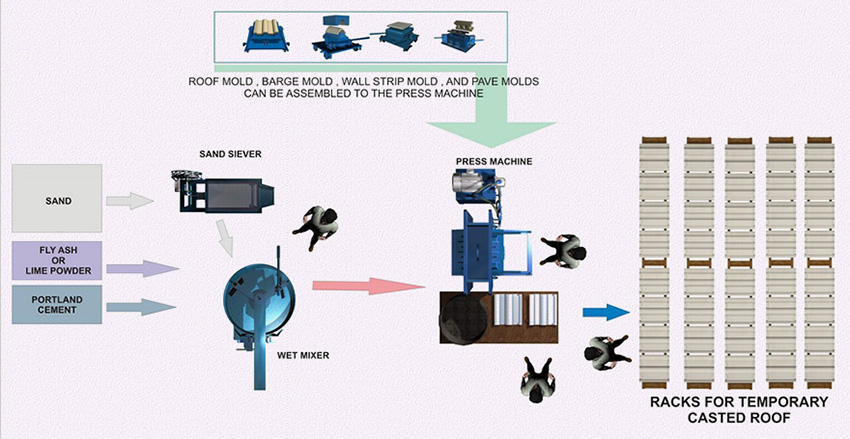

3. MATERIALS : |

3.1 BASIC

MATERIAL .

The basic

material for

producing

concrete roof

tiles are :

CEMENT and SAND

. But for making

the surface

smoother with

low cost , some

factories

especially in

Indonesia using

calsium powder .

We get Calcium

Powder in

Indonesia from

Calcium Mountain

. But in several

places , which

don't have

Calsium Powder ,

you can use

another material

as long as looks

like powder and

cheap enough .

But if there are

no another

material like

that , we can

use only Cement

and Sand , but

for surface

smoothing you

should use

pre-sieved sand

.

|

3.2 SECONDARY

MATERIAL :

Secondary

material , are

materials that

are used to help

the production

easier , and

some of them are

necessary . The

second material

are :

1. Textile : We

need textile for

layering the

Production Plate

, and we use

ordinary textile

that usually

used for making

trousers .

2. Brush : We

need Brush for

oiling the upper

mould surface ,

each time the

roof casted ,

for releasing

the roof tile

from the upper

mould .

3. Mould Oil :

The mould oil is

needed for

oiling the upper

mould surface

each time the

roof casted .

You can make the

Mould Oil by

yourself from 1

Liter Engine Oil

( better if you

use Engine Oil

for MotorBike )

, mixed with 10

Liter Kerosene .

|

3.3. MATERIAL

COMPOSITION :

BASIC MATERIAL :

For Roof :

The basic

materials

composition for

roof usually are

1 Cement + 2

Calsium Powder +

2 Sand . The

explanation of

this composition

is : Cement is

used for

Strength as the

tile need Cement

for it's final

strength .

Calsium Powder

is used for

surface

smoothing but we

also can use any

other material

for smoothing if

there isn't

calcium powder

in your area ,

like smaller

size sand , etc

.

In Indonesia we

use Calsium

Powder for

surface

smoothing

because it is

cheap . But in

some area which

Calsium Powder

aren't available

, then we can

use smaller size

sand ( sieved

sand ) . And the

last basic

material is Sand

, we need sand

for filling

material , sand

is the cheapest

material .

We can adjust

the 1 + 2 + 2

composition as

needed . We can

use 1 + 2 + 3 ,

or 1 + 2,5 + 2,5

. It is depend

on the kind of

material in your

area , and

depend of the

the roof quailty

you want to

produce .

For Pave :

The basic

materials for

Pave is just

Cement and Sand

, with

composition of :

1 Cement + 8

Sand , or 1

Cement + 10 Sand

, or 1 Cement +

12 Sand . The

more cement

factor the more

strong result

but also will

increase the

product cost and

price .

|

3.4 FINISHING

MATERIAL :

The finishing

material for

concrete roof is

PAINT . The

painting method

is using spray .

You need Air

Compressor Unit

and Spray Gun .

And you can used

any kind of

Paint for the

roof . But the

best Paint are

Concrete Roof

Paint , the

paint specially

produced for

concrete roof .

There are two

kind of concrete

roof Paint ,

water base and

oil base . Water

base is cheaper

, but Oil Base

is Shiny .

|

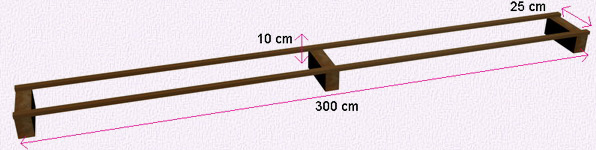

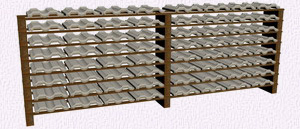

3.5. RACK :

You need to

prepare Racks

for temporary

tiles stay

during casting

process and to

leave the tiles

one day before

the tiles are

strong enough to

be released from

the pallets .

We usually use

Racks made from

wood / timber .

But you can use

any kind of

racks you like .

Our wood racks

model and

measurement is :

Length 300 cm ,

Width 25 cm ,

High 10 cm .

|

3.6. PALLETS

:

You need to

prepare

pallets ,

just use the

supplied "

Pallet Maker

" to produce

the pallets

. You only

need 1000

pcs of

pallets for

each roof

machine ,

and the

pallets can

be use for

more than 3

years . When

some pallets

broken ,

just use the

" Pallet

Maker " to

produce new

pallets .

Please Click

Here to

refer to the

Pallet Maker

explanation

. And

Click Here

for the

explanation

of Pallet

Preparation

for your

first time .

|

|

|

|

| |

|

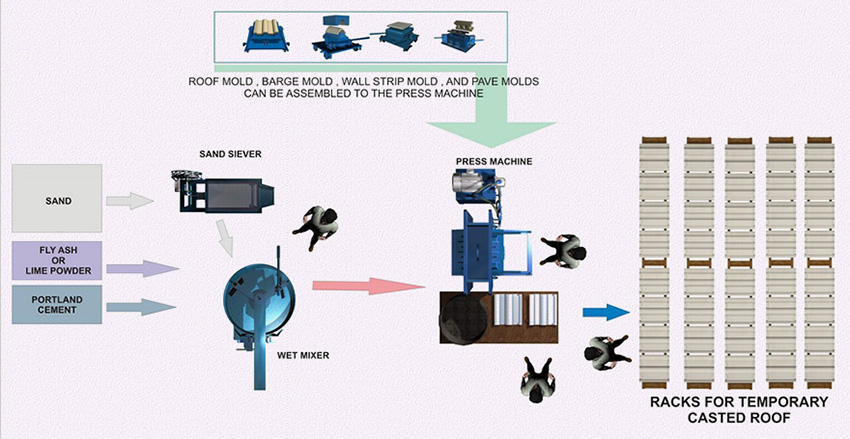

4. WORK FLOW AND

OPERATORS

: |

|

Explanation

of each worker

function :

Worker number 1

Works to sieve

sand and supply

the sand to dry

mixer

Workers number 1

also work at the

mixer and supply

the mortar to

the machine (

supply the

mortar

to temporary

container on the

table besides

the roof machine

) . These

workers are very

important , they

control your

material

composition (

cement and sand

) for your roof

production .

Worker number 2

Casting the roof

and deliver the

results to

worker number 3

.

Worker number 3

Worker number 3

also helping

serving to put

mortar to the

supporting plate

for the worker

number 2 .

Worker number 4

And helping

release the roof

from the

supporting plate

, reverse it on

to the pallet

and put to the

racks .

|

These Videos ( uploaded

at YouTube ) will show

you how the workers work

:

VIDEO 1 ( ROOF MACHINE )

VIDEO 2 ( ROOF MACHINE )

VIDEO 3 ( WALL ART

MACHINE )

VIDEO 4 ( PAVE MACHINE )

|

|

|

| |

|

5. CURING THE PRODUCTS : |

No particular system

needed to cure the

concrete roof , just

build some water tank

with any demension you

like , depend on the

capacity of the roof you

want to cure . Ususally

we use some water tank

with demension L4m x W3m

x H1m each . The best

curing time for concrete

products is minimum 24

hours , but will reach

the better strength if

we cure them for 3 x 24

hours ( 3 days ) .

|

|

|

| |

|

6. PAINTING : |

We can paint the

roof tiles after

they already dry

and strong

enough , usually

after 2 weeks

from the day we

take them out

from curing

water . Just use

the air

compressor and

spray gun to

paint the roof

tiles . Some of

factories paint

their roof tiles

on the top of

the roof's house

.

Two workers

usually can

spray 1000 tiles

per day ( 7

hours ) . Today

, there are many

brands of roof

paint , you can

easily buy the

roof paint in

the paint shop .

But we can also

give you the

formula to

produce your own

roof paint if

you want to

produce roof

paint by

yourself .

Click Here

for the

explanation of

how to paint the

roof tiles . |

|

|

|

|

If you have any questions regarding the

production of concrete roof tiles or

paver , please feel free to email us at

:

rudyiskandar86@hotmail.com or

rudy@supersonicmch.com

|

|

|

|